In modern power electronics, bidirectional DC power supplies are no longer unfamiliar to laboratories or production lines. From testing motors and batteries in new energy vehicles to R&D and verification of energy storage systems, and performance evaluation of photovoltaic inverters, these devices, capable of flexibly switching between power supply and load, are playing an increasingly crucial role. However, faced with a dazzling array of models and brands on the market, navigating the confusion and selecting the most suitable bidirectional DC power supply for your specific application has become a challenge for many engineers and technology decision-makers.

Understanding the Core: What is "Bidirectional"?

Understanding that of traditional DC power supplies, which can only output energy, the core of a bidirectional DC power supply lies in its ability to "flow energy in both directions."

Source Mode: In this mode, it acts as a sophisticated power supply, providing stable and adjustable DC power to the device under test (such as a DC-DC converter, on-board charger, etc.).

Sink Mode: In this mode, it transforms into an energy absorber, or regenerative load, capable of absorbing electrical energy generated by the device under test (such as batteries, photovoltaic panels, motor controllers, etc.) and efficiently feeding this energy back to the power grid or local grid, rather than dissipating it as heat.

This "dual-purpose" characteristic brings revolutionary advantages: energy saving and consumption reduction (especially significant electricity cost savings in high-power testing), space and cost savings (no need to purchase separate power supplies and loads), simplified testing systems (a single device enables charge-discharge cycle testing), and greatly improved testing efficiency.

Defining Requirements

Before making a selection, the most important and crucial step is to clearly define your application requirements. Any selection divorced from practical application is blind.

Application Scenario Analysis

Battery Testing: Requires simulating charge-discharge cycles, focusing on the accuracy of voltage and current and dynamic response speed.

New Energy Vehicle Electric Drive/Control Testing: May require simulating complex operating conditions, such as energy recovery during regenerative braking, requiring the power supply to have high dynamic performance and high-speed programming capabilities.

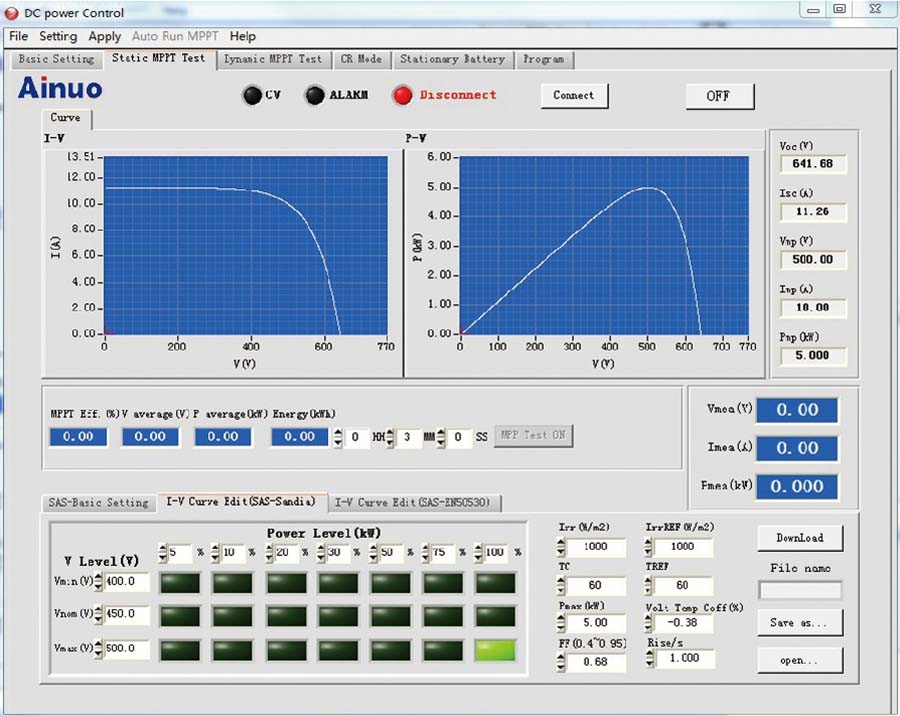

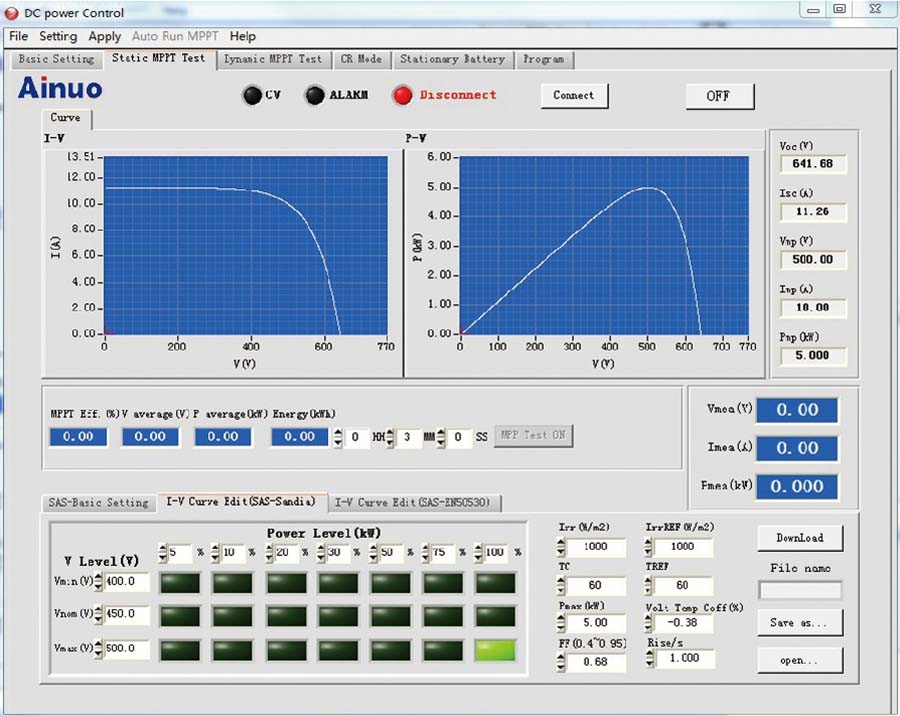

Photovoltaic Inverter Testing: This requires simulating the I-V curves of photovoltaic panels under different light and temperature conditions, demanding that the power supply possess arbitrary waveform generation and MPPT tracking testing capabilities.

Energy Storage Converter (PCS) Testing: This involves grid interaction and may require the power supply to simulate grid disturbances.

Power Module Aging Testing: This involves continuous high-power operation, placing extremely high demands on the reliability and stability of the equipment.

Key Performance Parameters

Voltage and Current Range: This is the most basic requirement. It's not enough to just look at the maximum value; the output/absorption capacity across the entire operating range must be considered. For example, a device may have a nominal maximum voltage of 1000V, but may not be able to provide the rated power at lower voltages. Always use a voltage-current (V-I) curve to confirm the device's true capability across the entire range.

Power Rating: Determined based on the maximum power of the device under test, with a 20%-30% margin recommended to accommodate peak power and potential future upgrades.

Accuracy and Resolution: The setting and measurement accuracy of voltage and current directly affect the reliability of the test results. High accuracy is crucial for applications such as R&D and calibration. Dynamic Response Speed: This refers to the rate of change of voltage/current, usually expressed as rise/fall time (Slew Rate). High-speed dynamic response is essential for dynamic scenarios such as simulating battery charging and discharging, and sudden changes in motor load.

In-depth Technical Details

After clarifying the basic requirements, it is necessary to examine the following core technologies and functions in depth, as they determine the upper limit and applicability of the equipment.

Topology and Efficiency

The core topology of a bidirectional DC power supply determines its performance. Currently, the mainstream approach uses a two-stage structure of bidirectional PFC + bidirectional DC/DC. This structure achieves highly efficient energy feedback (typically >90%), a high power factor (PF>0.99), and low grid interference (low THDi). Understanding its topology helps in assessing the manufacturer's technical capabilities and the product's energy efficiency level.

Feedback Mechanism and Grid Friendliness

How energy is fed back to the grid is a key differentiator. High-quality bidirectional power supplies should employ pure sine wave feedback technology to ensure that the current injected into the grid is clean and does not pollute the grid, meeting stringent grid standards (such as EN 50549, IEEE 1547). This is not only a responsibility to the public power grid but also prevents harmonic interference from affecting the normal operation of other precision equipment in the laboratory.

Control and Programming Capabilities

Sequence Function: The ability to edit complex multi-step sequences to simulate real-world operating cycles (such as battery charge/discharge pulse tests) greatly improves automated testing efficiency.

Arbitrary Waveform Generation Function: The ability to output or simulate custom voltage/current waveforms to simulate non-ideal signals such as battery internal resistance changes and engine start-up pulses.

List Function: The ability to quickly switch voltage and current settings for dynamic stress testing.

Simulated Photovoltaic Array Function: Built-in mathematical models of photovoltaic panels allow direct simulation of I-V curves for different brands and specifications of photovoltaic panels, making it a powerful tool for testing photovoltaic inverters.

Measurement and Data Analysis Functions

A good bidirectional power supply is not only an actuator but also a high-precision data acquisition device. Pay attention to the measurement accuracy, sampling rate, and data logging capabilities of its voltage, current, and power measurements to record data during testing for subsequent analysis and report generation.

Interfaces and Integration

In modern test systems, equipment must be easily integrated. Besides standard GPIB, USB, and LAN interfaces, industrial real-time Ethernet interfaces such as EtherCAT are becoming standard on high-end equipment. They enable extremely low communication latency and precise synchronization, suitable for parallel connection of multiple power supplies or integration with other equipment into complex test benches.

Parallel Connection and Expansion Capabilities

As test power increases or test requirements expand, a single device may not be sufficient. Therefore, assessing the seamless parallel connection capability of the equipment is crucial. A truly excellent parallel connection solution should achieve the following:

Automatic Master-Slave Setup: The system automatically identifies master and slave units with simple user operation.

Current Sharing Control: Ensures balanced output current across all units, preventing overload of any single unit.

Single Control Point: Users only need to program and control the master unit, just like operating a high-power power supply.

This makes it possible to expand system power in the future with minimal cost.

Software and User Experience

Hardware is the skeleton, software is the soul. Intuitive, powerful, and stable control software can exponentially improve the efficiency of engineers. Both the device's built-in graphical interface and the accompanying PC software should be easy to operate and provide comprehensive drivers (such as IVI, LabVIEW, .NET, etc.) and programming examples to facilitate secondary development and system integration.

Brand, Service, and Support

Finally, but by no means the least important, is the manufacturer's soft power.

Brand and Technical Reputation: A long history and a good industry reputation are usually endorsements of reliability and technological maturity.

Technical Support: Can the manufacturer provide timely and professional technical consultation and troubleshooting support?

Calibration and Repair Services: Is the service network comprehensive? What are the calibration cycles and costs?

Warranty Policy: The warranty period and terms reflect the manufacturer's confidence in the quality of its products.

Conclusion

Choosing a suitable bidirectional DC power supply is a systematic process from "knowing yourself" (clarifying your own needs) to "knowing the other" (deeply understanding the product technology). It is not simply a comparison of parameters, but a comprehensive consideration of the device's performance, functionality, efficiency, scalability, and the overall strength of the manufacturer behind it. A meticulous upfront investment will provide you with a stable, reliable, and energy-efficient testing partner for years to come, offering a solid guarantee for your research and verification work.