Part 1: Technical Difficulties of Simulating Lithium Battery Characteristics with Traditional DC Test Power Supply

The core of a traditional DC power supply (or power/load system) is to provide a stable and precise voltage or current. However, lithium batteries are nonlinear and dynamically changing chemical power systems. Using the former to simulate the latter presents the following technical difficulties:

Unable to simulate the battery's dynamic internal resistance

Difficulty: The internal resistance of a lithium battery is not a fixed value; it changes in real time with changes in state of charge (SOC), temperature, state of health (SOH), and charge and discharge current. The output impedance of a conventional power supply is typically fixed and extremely low.

Consequence: When the operating current of the device under test (DUT) (such as a battery protection system (BMS)) changes, the terminal voltage of the actual battery will "dip" or "swell" due to this change in internal resistance. Conventional power supplies cannot replicate this dynamic response, resulting in distorted test results and failing to expose real-world issues (such as voltage sampling errors and incorrect protection point triggering timing).

Unable to accurately simulate a battery's open-circuit voltage (OCV)-state of charge (SOC) curve

Difficulty: The relationship between a lithium battery's voltage and its remaining charge (SOC) is a highly nonlinear curve, including plateaus and steep rises and falls. Conventional power supplies typically only allow for a fixed voltage or a simple voltage sequence.

Consequence: Unable to simulate the battery's charge and discharge process, especially the slow voltage change during the plateau phase (from 20% to 80% charge), nor the sharp drop in voltage when the battery is depleted. This is crucial for testing the gas gauge algorithm in a battery management system.

Energy Regeneration Issue - Core Difficulty

Difficulty: When simulating battery discharge, the device under test (e.g., charger, DC-DC converter) actually "injects" energy into the power supply. Conventional electronic loads simply dissipate this energy as heat.

Consequence:

Large energy consumption: High-power testing requires a large cooling system, resulting in extremely high electricity costs.

Severe Heat: Excessive heat can alter the test environment temperature, potentially affecting the accuracy of the device under test (DUT) and placing significant strain on the laboratory's air conditioning system.

Mode Switching Delay and Voltage and Current Overshoot

Difficulty: Testing often requires switching between constant current (CC) and constant voltage (CV) modes (for example, simulating the inflection point when a charger switches from CC to CV charging). Mode switching for common power supplies/loads has millisecond-level delays, which can easily cause voltage or current overshoots.

Consequences: Overshoots in voltage or current can damage expensive DUTs (such as mobile phone motherboards and chips) or trigger their protection mechanisms, resulting in test interruption and inability to verify their performance under normal operating conditions.

Weak Simulation Capabilities for Complex Operating Conditions

Difficulty: Simulating complex real-world operating conditions is difficult, such as the high current pulses during car startup, the recovery effect (voltage recovery after a sudden load removal), and battery aging (increased internal resistance and capacity loss).

Consequences: Test coverage is limited, and many potential issues are only exposed during actual product use, increasing post-sales risks and development costs.

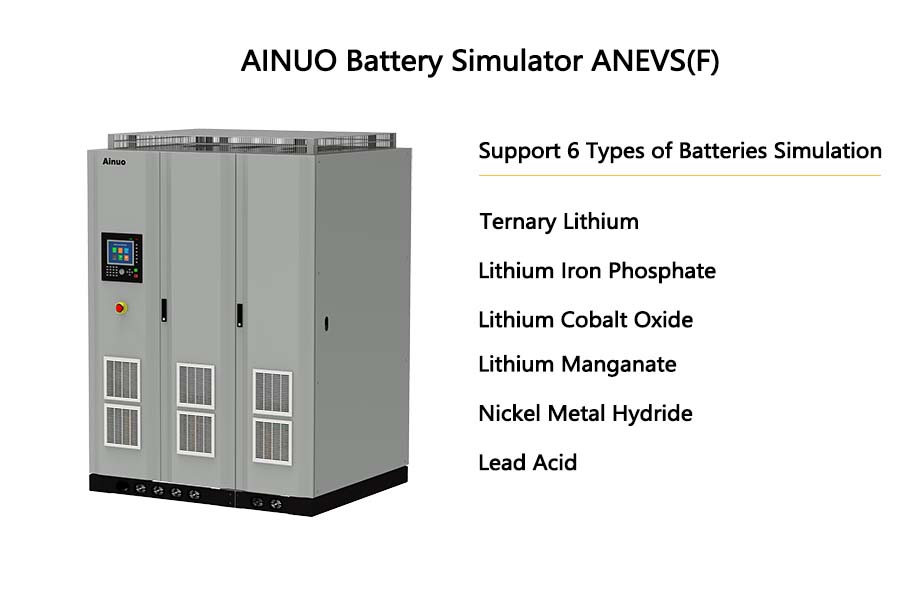

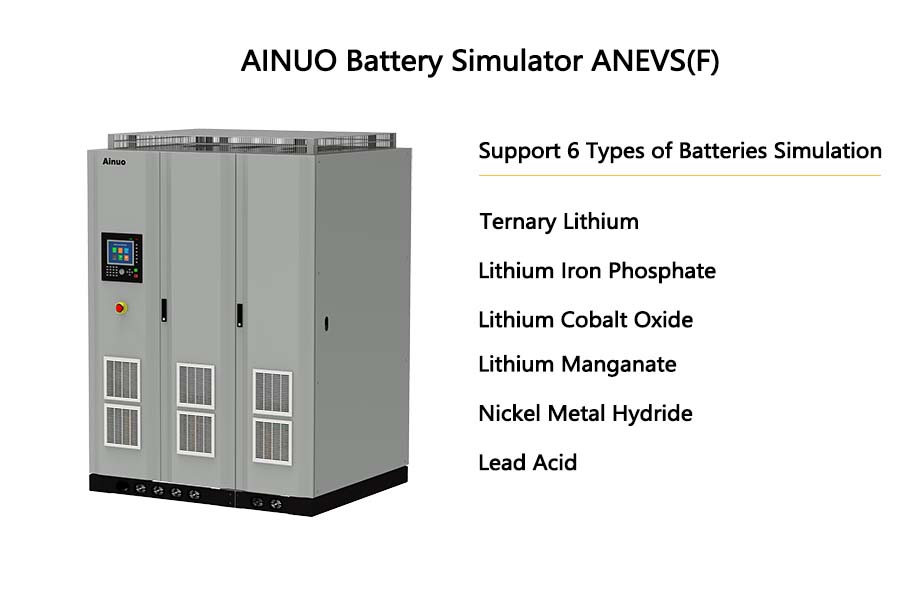

Part 2: Advantages of the ANEVS Series Battery Simulator

Professional battery simulators (taking the ANEVS series you mentioned as an example) were designed to address all of the aforementioned challenges. Their core advantages are as follows:

Accurate Battery Model Simulation

Advantages: Built-in, highly accurate battery mathematical models allow users to customize parameters such as battery type (e.g., ternary lithium, lithium iron phosphate), capacity, internal resistance, and SOC-OCV curve. They can calculate and simulate the battery's actual terminal voltage behavior at different SOCs in real time, including the effect of dynamic internal resistance.

High-Efficiency Energy Recycling (>90%)

Advantages: This is a revolutionary advantage of battery simulators over conventional loads. The ANEVS series recycles and feeds discharged energy back into the grid instead of converting it into heat.

Benefits:

Energy Saving and Environmental Protection: Significantly reduces energy consumption and electricity costs, achieving energy savings of over 80%.

Reduced Heat: The laboratory environment is cooler and more comfortable, eliminating the need for significant investment in cooling facilities.

Green Philosophy: Meets the modern corporate social responsibility requirements of energy conservation and emission reduction.

Seamless Mode Switching and Overshoot-Free Design

Advantages: Advanced digital control technology enables nanosecond-level fast mode switching and seamless transitions.

Benefits: Completely eliminates the risk of voltage and current overshoots, effectively protecting the device under test and ensuring a smooth, continuous, and accurate testing process. It is particularly suitable for testing devices with smart charging protocols.

Comprehensive Simulation Functions and Test Scenarios

Advantages:

Working Condition Simulation: Programmable simulation of charge and discharge curves, pulse operating conditions, and battery aging (increasing internal resistance and reducing capacity).

Multiple Operating Modes: Supports not only battery simulation mode, but also standard power mode, standard load mode, and CR-LED mode, enabling multiple uses in one device.

Sequence Function: Edit complex multi-step sequences to simulate real-world charge and discharge cycles.

High Power Density and Modular Design

Advantages: The ANEVS series features a high power density design, saving rack space. Select models support master-slave paralleling, easily expanding power and current to meet high-power testing needs (such as new energy vehicle and energy storage system testing).

Comprehensive Software Support and Integration

Advantages: Powerful host computer software allows for graphical editing of battery parameters and test curves. Support for instruction sets in programming languages such as LabVIEW, C#, and Python facilitates integration into automated test systems.

Features | Traditional DC test power supply | Battery Simulator (ANEVS) |

Internal Resistance Simulation | Fixed, difficult to simulate | Dynamically adjustable, highly realistic |

SOC-OCV Curve | Difficult to simulate | Accurate simulation, customizable |

Energy processing | Dissipated as heat | fed back to the grid, highly energy-efficient |

Mode switching | Delayed, prone to overshoot | Seamless switching, no overshoot |

Complex operating conditions | Difficult to implement | Easy simulation, rich functionality |

Testing costs | High (electricity costs, heat dissipation) | Low (energy savings) |

Core purpose | Provides stable DC power | Simulates real-world battery behavior |

Conclusion

For simple voltage/current supply tests, traditional test power supplies are sufficient. However, when verifying product performance in a real-world battery-powered scenario—for example, in R&D and certification testing of BMS, portable electronics, new energy vehicle motor controllers, and energy storage PCS—using a professional battery simulator (such as ANEVS) not only improves test accuracy and reliability but also offers a wise long-term investment in overall cost savings (electricity costs, heat dissipation, and equipment damage risk).