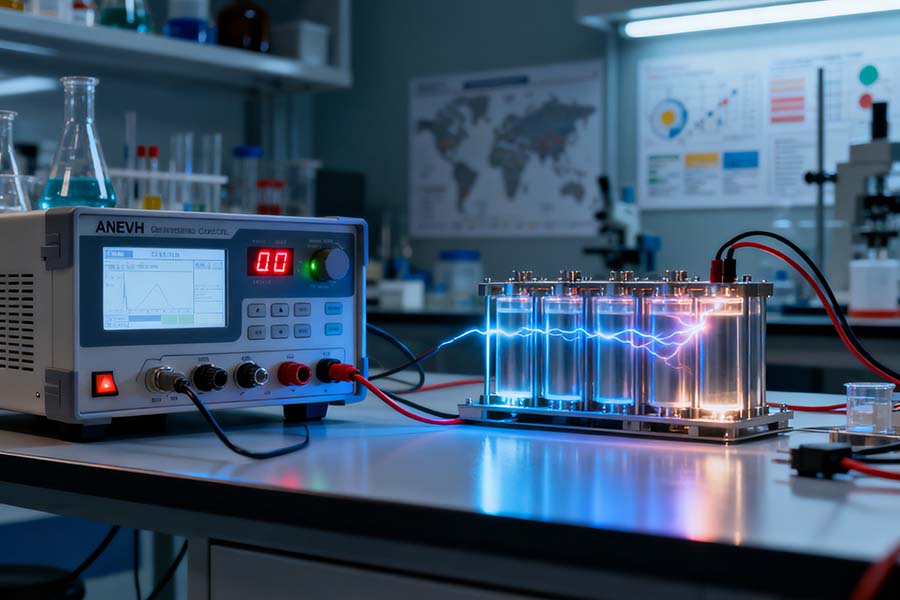

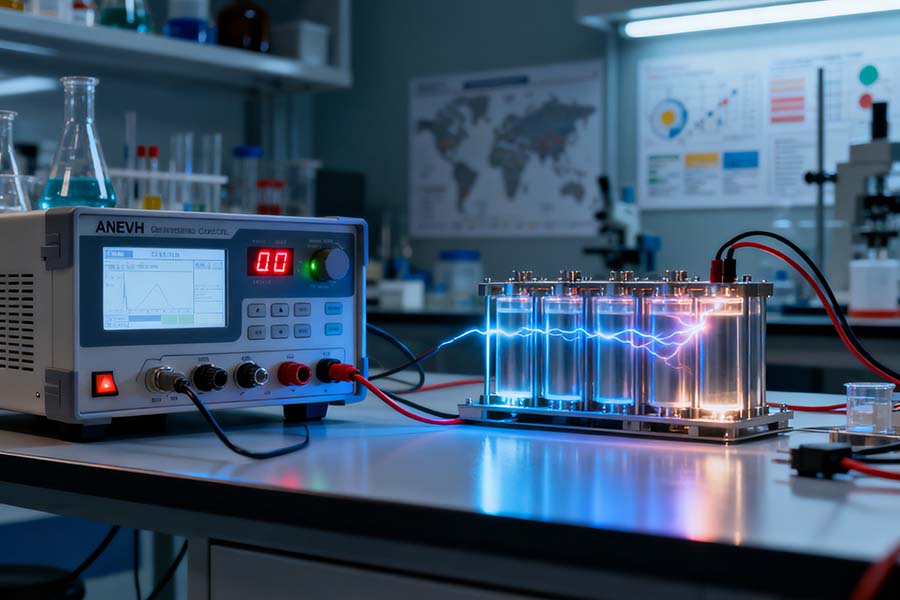

The race for a sustainable energy future is powered by innovation, particularly in solar and fuel cell technologies. In research and development labs worldwide, engineers are tirelessly working to improve the efficiency, durability, and cost-effectiveness of these green energy sources. But behind every breakthrough, there's often an unsung hero enabling the testing and validation process: the Programmable Bi-Directional DC Power Supply.

While a standard power supply is a one-trick pony—providing DC power to a device under test—a bi-directional supply is a versatile workhorse. It can both source and sink power with precision. Think of it as a sophisticated, programmable battery emulator.

·Source Mode: It acts as a traditional power supply, providing stable DC voltage or current to a device (e.g., powering an inverter).

·Sink Mode: It acts as an electronic load, dynamically absorbing current and power from a device (e.g., from a solar panel or fuel cell).

The "programmable" aspect is what makes it so powerful for R&D. Every parameter—voltage, current, power, and even complex dynamic sequences—can be controlled remotely via software, allowing for automated, repeatable, and data-rich experiments.

1. Key Advantages of Programmable Bidirectional DC Power Supply for the Modern R&D Lab

Why is this instrument so crucial? It consolidates functionality, enhances accuracy, and unlocks new testing possibilities.

1.1 Unmatched Versatility in a Single Instrument

It replaces the need for a separate DC power source and a separate electronic load, saving bench space, reducing costs, and simplifying test setup.

1.2 Energy Recovery (Regeneration)

This is a game-changer for cost and sustainability. When sinking power, a high-quality bi-directional supply can convert that absorbed energy and send it back to the grid or another part of the lab, drastically reducing electricity bills and heat output compared to traditional loads that dissipate energy as heat.

1.3 Seamless Quadrant Operation

It can operate seamlessly in all four quadrants of the voltage-current (V-I) plane, allowing it to simulate real-world scenarios where a device might switch instantly from providing power to consuming it.

1.4 Precision and Data Integrity

With high-accuracy measurement and data logging capabilities built in, it provides a single, trusted source for voltage, current, and power data during tests, which is critical for calculating efficiency and characterizing performance.

2. Powering Innovation in Solar and Fuel Cell R&D

So, how exactly is this tool applied to the cutting edge of renewable energy?

2.1 Emulating Solar Panels for Inverter Testing

Solar inverters are complex devices that must efficiently convert the variable DC output from photovoltaic (PV) panels into grid-compliant AC power. To test an inverter, you can't rely on the sun alone—you need a repeatable, controllable source.

A bi-directional power supply excels here by emulating a solar panel's I-V curve. Researchers can program it to:

·Simulate specific irradiance and temperature conditions.

·Replicate the daily rise and fall of the sun.

·Mimic rapid cloud-cover transients.

·Perform Maximum Power Point Tracking (MPPT) efficiency tests by sweeping voltage and measuring where the inverter draws the most power.

This enables engineers to validate inverter performance, efficiency, and stability under a wide range of controlled laboratory conditions, thereby accelerating development cycles.

2.2 Testing Grid-Tie Inverters and Anti-Islanding Protection

A critical safety feature for any grid-tied inverter is "anti-islanding." If the grid goes down, the inverter must shut off to prevent sending power to lines that utility workers might think are dead. Testing this requires a tool that can both power the inverter and absorb its power.

The bi-directional supply acts as the grid emulator:

·It initially sources power to run the inverter.

·Once stable, it sinks the AC power the inverter produces (by converting it to DC).

·To test anti-islanding, it suddenly stops sinking power, simulating a grid failure. The test verifies that the inverter detects this and shuts down within the required time.

2.3 Characterizing Fuel Cell Stacks

Fuel cells generate DC electricity through an electrochemical reaction. Characterizing their performance is fundamental to R&D. A bi-directional supply is instrumental in:

·Polarization Curve Measurement: By acting as a variable load (sinking power), the supply can sweep current levels while precisely measuring the resulting voltage drop of the fuel cell stack. This produces the critical polarization curve that reveals performance characteristics and inefficiencies.

·Durability and Cycle Testing: To test longevity, researchers can program the supply to apply repetitive load cycles, simulating the real-world start-stop and variable demand a fuel cell would experience in a vehicle or a stationary power system.

2.4 Developing DC-DC Converters and Power Management Systems

Both solar and fuel cell systems rely on sophisticated DC-DC converters to manage their variable output. A bi-directional supply can test these converters by:

·Sourcing Power: To simulate the fuel cell or solar panel input, testing the converter's efficiency under different input conditions.

·Sinking Power: To simulate the battery or grid on the output side, testing the converter's regulation and control algorithms.

3. Conclusion

The programmable bi-directional DC power supply is far more than just a "power supply." It is a fundamental enabler of the energy transition. By providing the flexibility to emulate, absorb, and measure with precision, it allows researchers to de-risk designs, prove efficiency gains, and ensure the safety and reliability of the solar and fuel cell technologies that will power our future. In the quest for cleaner energy, it’s the versatile, powerful, and intelligent tool that helps turn brilliant ideas into a tangible, testable reality.