Industry Background

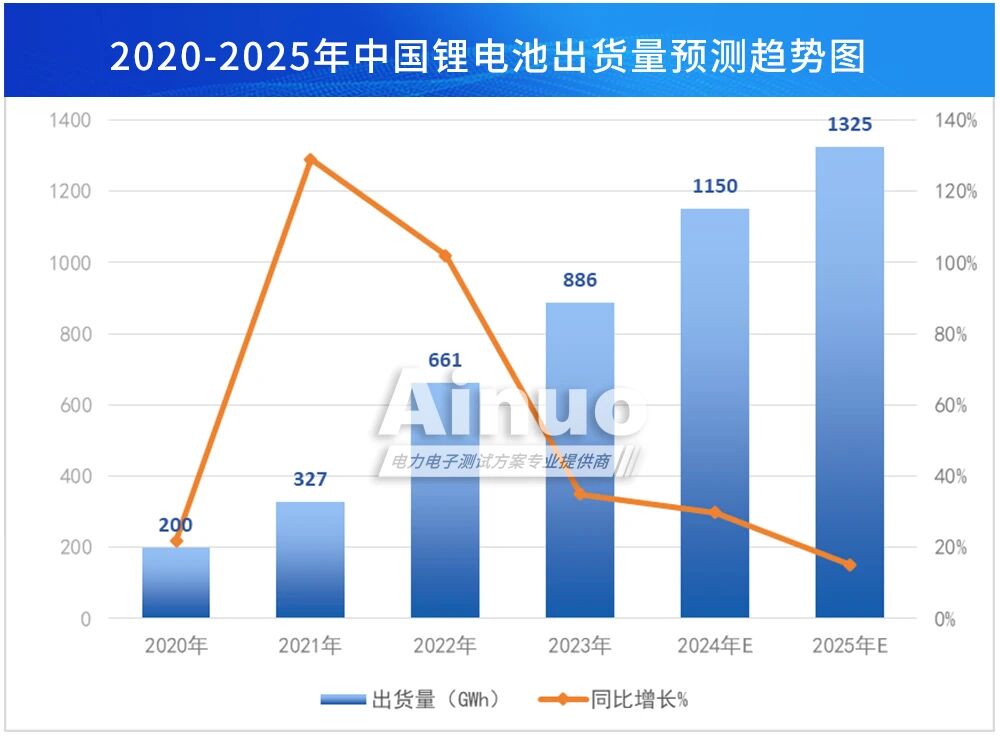

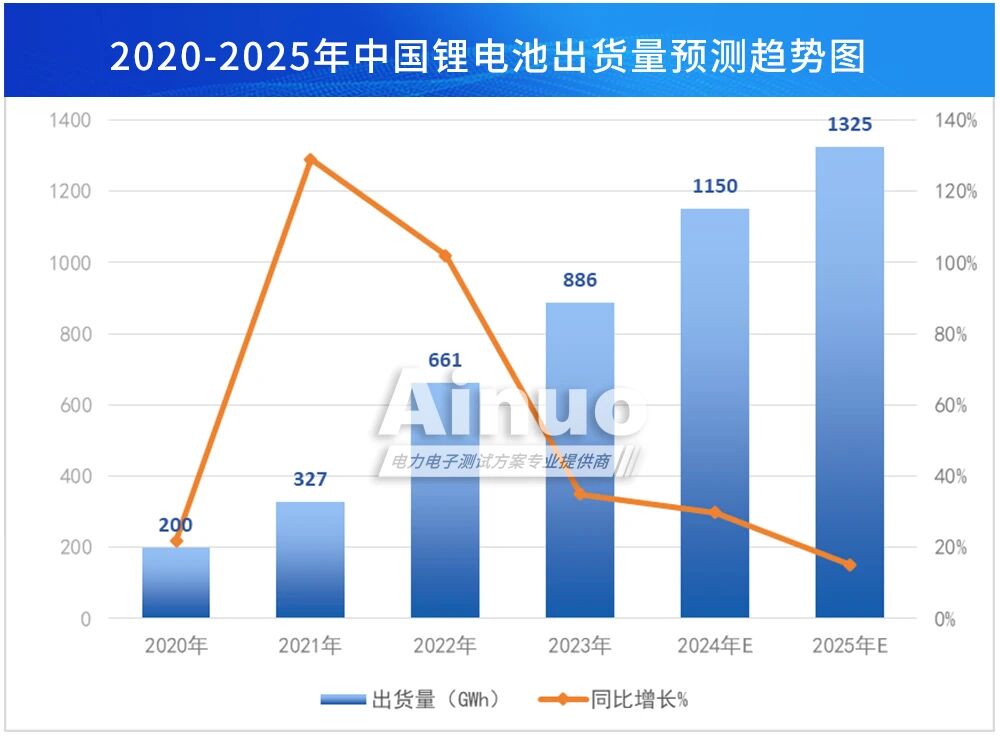

Driven by demand from electric vehicles, energy storage, and consumer electronics, my country's lithium battery industry maintains a growth momentum. According to GGII data, my country's lithium battery shipments reached 886GWh in 2023, a year-on-year increase of 35%, and shipments are expected to exceed 1,325GWh in 2025.

Application Demand

To promote technological advancement and product quality upgrades in the lithium battery industry, the Ministry of Industry and Information Technology (MIIT) has issued the "Lithium Battery Industry Standard Conditions (2024 Edition)." This requires manufacturers to possess the capabilities to perform internal short-circuit high-voltage testing of battery cells, consistency testing of open-circuit voltage and internal resistance, online testing of battery pack protection devices, and testing for harmful impurities in positive and negative electrode materials. It also sets higher and more specific performance indicators for various battery types, including safety, energy density, power density, and cycle life.

Testing Difficulties and Solutions

1. Testing Difficulties (Characteristics of OCV Measurement)

In the production, R&D, and cascade utilization of lithium batteries, self-discharge performance evaluation is essential to ensure battery safety and battery pack voltage consistency. Self-discharge performance testing methods primarily include the open-circuit voltage (OCV) method, the self-discharge current (SDI) method, and the dynamic equivalent circuit (EIS) method.

The OCV method is the most commonly used and reliable method for testing lithium battery self-discharge performance. It uses the K value (K) of lithium batteries for identification and screening. The K value testing process and calculation formula are as follows:

K = (V1 - V2) / ΔT

Where: V1 is the OCV of the first test, V2 is the OCV of the second test, ΔT is the time interval between the two measurements, and the K value is expressed in mV/h or mV/d.

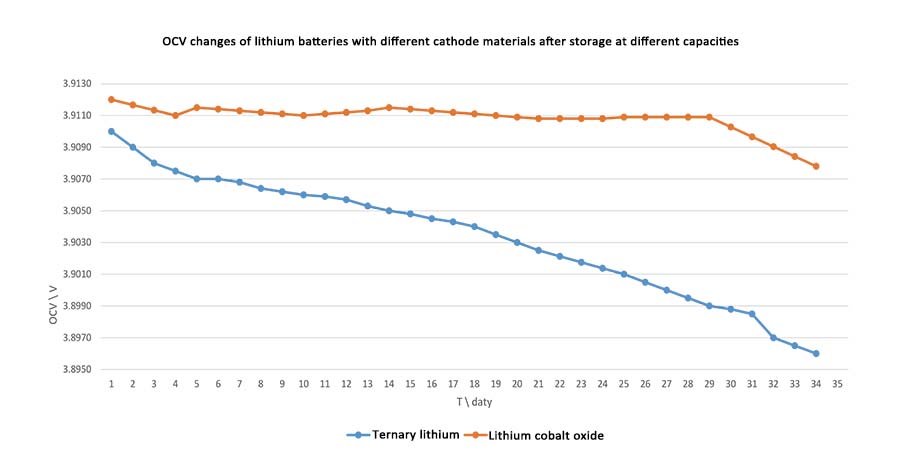

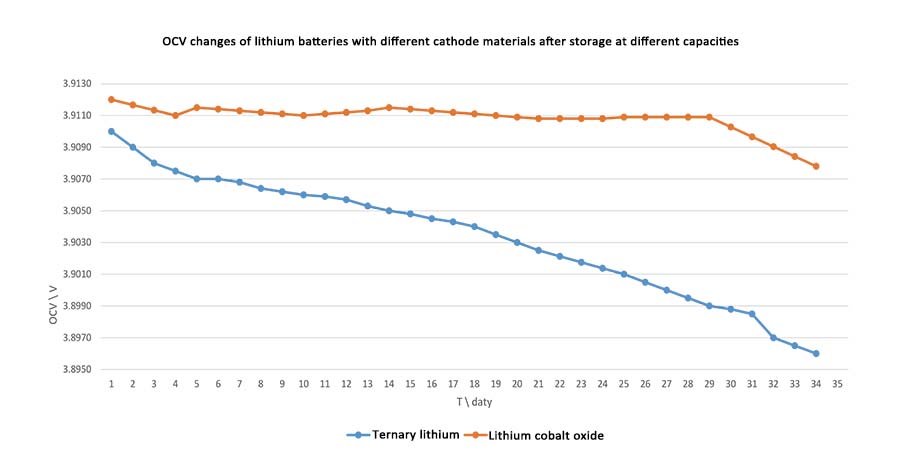

For batches of lithium batteries under the same testing conditions, the K value changes very little after a certain period of quiescence. Furthermore, the OCV drop varies among different cathode materials. The OCV measurement resolution required for K value calculation must be at least 0.1 mV. Therefore, the DC voltage used for OCV testing generally requires a display resolution of 7.5 digits.

2. Solution

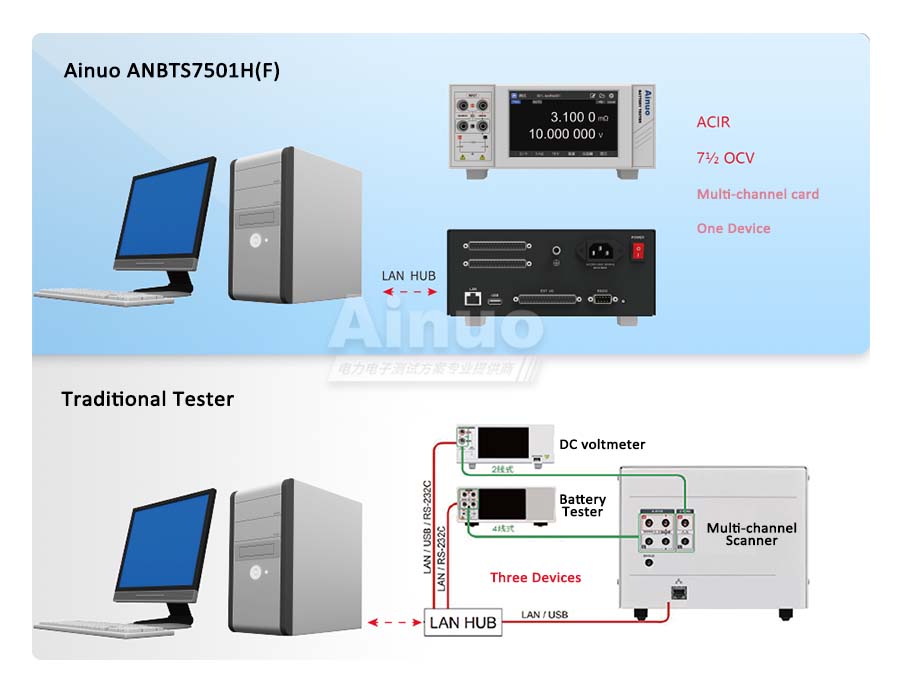

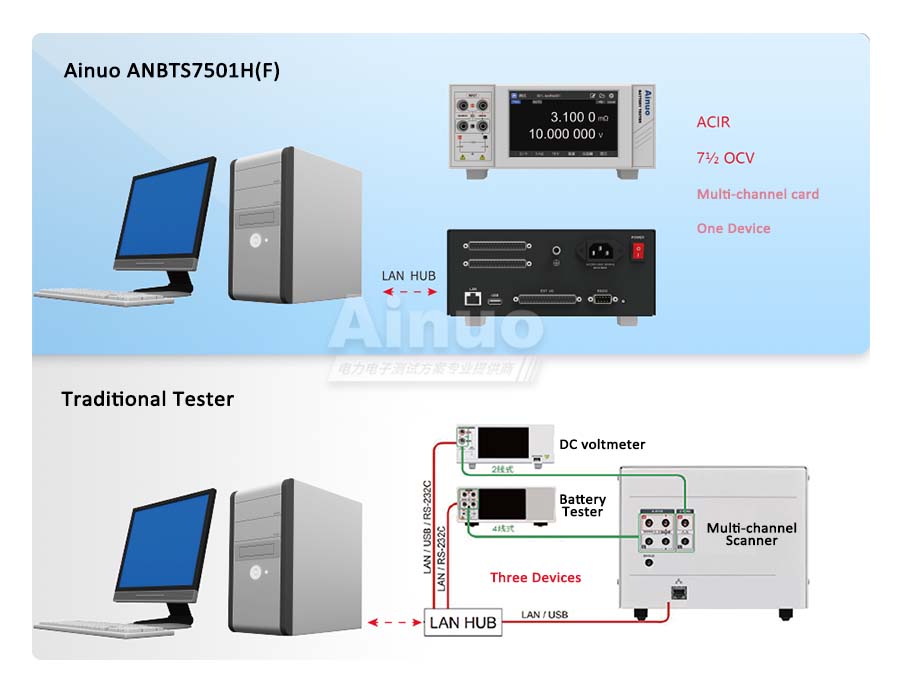

Ainuo has been deeply involved in the testing industry for many years and provides full-process testing solutions for the lithium battery industry. To address the testing difficulties in lithium battery self-discharge performance screening and production processes, we have newly developed and launched the high-precision battery testers ANBTS7501H (MAX 100V) and ANBTS7510H (MAX 1000V). Leveraging a highly stable reference voltage source, automatic calibration technology, and anti-interference capabilities, they provide 7.5° high-resolution DC voltage, AC internal resistance, and multi-channel scanning comprehensive testing. They are widely applicable to open circuit voltage (OCV) and AC (ACR) measurements of single cells, battery modules, battery packs, and energy storage cabinets.

Applications

Scenario 1: K-value Screening: High-precision voltage measurement for aging single cells allows for rapid screening of poor K-values, improving testing efficiency.

Scenario 2: Consistency Sorting: Voltage consistency and precise matching for battery modules, battery packs, and energy storage cabinets.

Scenario 3: Battery R&D: High precision, high resolution, high stability, and ease of use make it an ideal tool for R&D, testing, and analysis.

Scenario 4: Battery Recycling: Two-in-one open-circuit voltage and AC internal resistance measurement with a wide range and high precision for rapid identification of problematic batteries.

Product Features

Three-in-one: Integrates a high-precision DC voltmeter, AC internal resistance meter, and multi-channel scanner.

High Precision: 7.5° resolution (10nV-1000V voltage), 5.5° resolution (0.1uΩ-3kΩ AC internal resistance).

Compensation: Automatic conversion to standard temperature and voltage, automatic voltage and resistance zero-point compensation.

Ease of Use: Touchscreen operation, equipped with multiple interfaces: RS232, LAN, I/O, and USB.

Conclusion

Ainuo Instruments provides comprehensive testing solutions for the lithium battery industry: We offer the ANBTS7201 series pulse short-circuit tester for battery cell assembly, the ANBTS7501H precision battery tester for battery cell fractionation and capacity analysis, and the ANBTS7520 battery tester, AN7510H precision battery tester, and the AN7438H series intelligent safety analyzer for battery packs/battery packages and energy storage cabinets. With 30 years of experience in electrical testing, Ainuo Instruments leverages its technological expertise to efficiently address testing challenges across the industry, earning the recognition and trust of numerous outstanding customers.